If you’re looking for a quick and easy way to cut a bolt, then you’ve come to the right place. In this article, we’ll show you how to do it in just a few simple steps.

Checkout this video:

Introduction

Bolts are one of the most common pieces of hardware used in a wide variety of applications. They are often used to secure two pieces of metal together, but can also be used in masonry and woodworking. Cutting a bolt is a relatively simple task that can be accomplished with a few basic tools.

Bolts are most commonly cut using a power drill with a metal cutting bit, but can also be cut using an angle grinder or a hacksaw. The type of tool you use will depend on the size and type of bolt you are cutting, as well as the amount of time and effort you are willing to expend.

No matter which method you choose, there are a few basic steps you will need to follow in order to ensure a clean, precise cut. In this guide, we will walk you through the process of cutting a bolt using three different methods.

What You Will Need

In order to cut a bolt, you will need a few tools. A power drill is the fastest way to get the job done, but you can also use a hand drill or a hacksaw. You will also need a high-speed steel (HSS) drill bit that is the same diameter as thebolt shaft. If you are using a power drill, you will need a drilling speed of between 500 and 1,000 revolutions per minute (rpm).

If you are using a hand drill, you can use any type of HSS bit. For best results, use a sharpening stone to keep the bit sharp. When cutting bolts with a hacksaw, you will need to use a bi-metal hacksaw blade. These blades are made of two types of metal that are welded together. The teeth of the blade are made of high-speed steel (HSS), while the body of the blade is made of carbon steel. This combination makes for a very tough and durable blade that can easily cut through bolts.

Step One: Measure the Diameter of the Bolt

Bolts come in a variety of diameters, so it’s important to measure the diameter of the bolt you need to cut. You can use a vernier caliper for an accurate measurement, or you can use a Bolt Size Chart if you don’t have a caliper. Once you know the diameter of the bolt, select a cutting die that is slightly smaller than the diameter of the bolt. This will ensure that your cut is clean and precise.

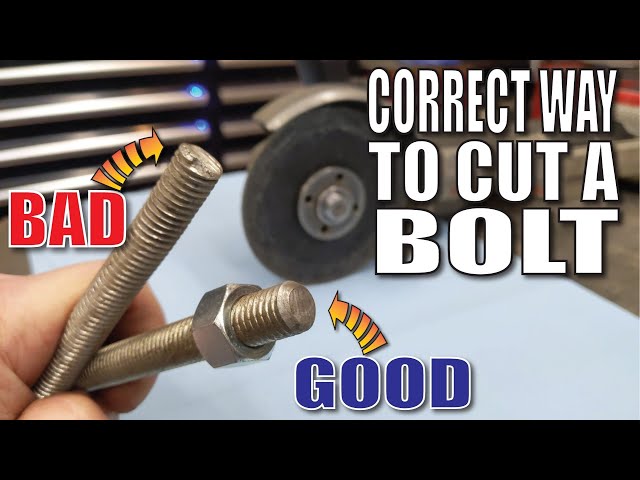

Step Two: Cut the Bolt

Now that the head of the bolt is removed, you need to cut the bolt. You can do this with a hacksaw, a power saw or a rotary tool. If you are using a power saw, be sure to use a blade designed for metal. If you are using a rotary tool, use a cutting wheel designed for metal.

When cutting the bolt, be sure to leave enough of the shank (the part of the bolt that extends past the head) so that you can grip it with a wrench or pliers. If you are unsure how much to leave, err on the side of leaving too much rather than too little. Once you have cut the bolt, use a file or grinding wheel to remove any sharp edges from the cut end of the shank.

Step Three: Deburr the Edges of the Bolt

Now that the bolt is cut, it’s time to remove any sharp or jagged edges. A sharp edge on a bolt can cause all sorts of problems, including cutting through electrical insulation and causing shorts. Use a file or a deburring tool to remove any sharp edges from the circumference of the bolt.

Conclusion

Now that you know the different types of bolt cutters and how to use them, it’s time to put your new skills to the test. Practice on some spare bolts or old pieces of metal before cutting anything important. With a little practice, you’ll be able to cut through bolts like a pro!